过载保护装置能在过载时立即将输入和输出断开,保护机械。 切实检测过载,驱动键从槽中脱开以切断输入和输出,去除过载后再次以相同转矩·相同分度位置自动连接。 转矩设定通过内置的转矩弹簧进行,无需微调等繁琐的作业。另外,还可起到挠性联轴器的作用,可在双轴对接或包覆式连接中任意一种方法下使用。并因是由驱动键传动,所以在油中也可使用。

用途半导体制造装置、纺织机械、印刷机械

过载保护装置能在过载时立即将输入和输出断开,保护机械。 切实检测过载,驱动键从槽中脱开以切断输入和输出,去除过载后再次以相同转矩·相同分度位置自动连接。 转矩设定通过内置的转矩弹簧进行,无需微调等繁琐的作业。另外,还可起到挠性联轴器的作用,可在双轴对接或包覆式连接中任意一种方法下使用。并因是由驱动键传动,所以在油中也可使用。

用途半导体制造装置、纺织机械、印刷机械

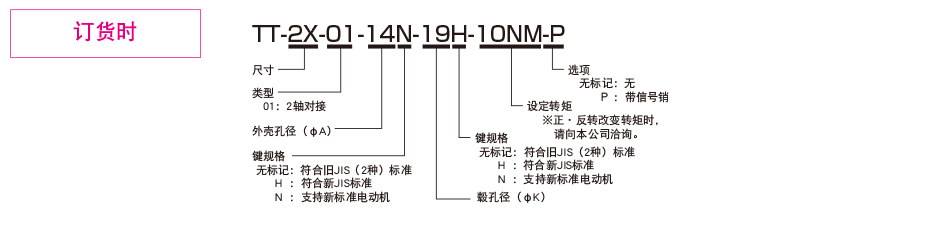

TT-□-01型

【规格】

| 型 号 | 尺寸 | 设定转矩值[N•m] | 允许误差 | 最高转速[min-1] | 转动惯量[kg•m2] | 质量[kg] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 弹簧颜色分类 | 偏心 | 偏角 | |||||||||||||

| 无色 | 蓝色 | 红色 | 黄色 | 白色 | 灰色 | 绿色 | 棕色* | 无色* | [mm] | [°] | |||||

| TT-1X-01 | 1X | 0.2 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 0.2 | 0.5 | 1800 | 0.06×10-3 | 0.3 |

| TT-2-01 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 0.2 | 0.5 | 1800 | 0.26×10-3 | 0.7 |

| TT-2X-01 | 2X | 2 | 3 | 5 | 8 | 10 | 12 | 15 | 18 | 20 | 0.2 | 0.5 | 1800 | 0.52×10-3 | 1.0 |

| TT-3-01 | 3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 0.2 | 0.5 | 1800 | 1.23×10-3 | 1.5 |

| TT-3X-01 | 3X | 10 | 16 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 0.2 | 0.5 | 1800 | 1.94×10-3 | 2.7 |

| TT-4X-01 | 4X | 20 | 30 | 50 | 80 | 100 | 120 | 150 | 180 | 200 | 0.2 | 0.5 | 500 | 14.8×10-3 | 6.3 |

※上表设定的转矩值为转速1500min-1时的数值。

※*部分的转矩需要耐久性时,请增大尺寸。

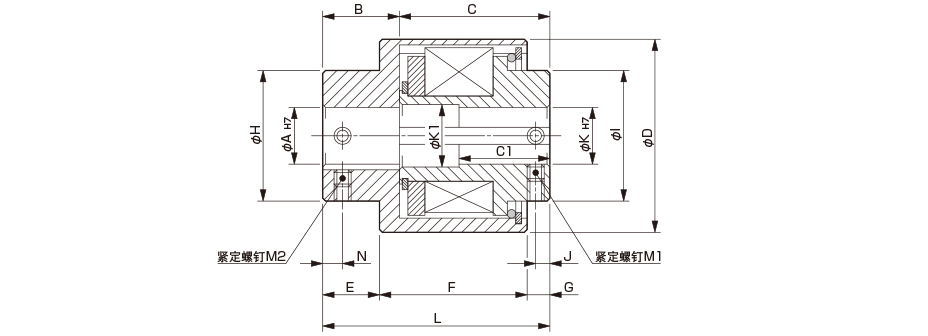

【尺寸】

| 尺寸 | 符合新JIS标准的轴孔尺寸A | 符合新JIS标准的轴孔尺寸K |

|---|---|---|

| 1X | 10, 11, 12, 14 | 10, 11, 12 |

| 2 | 11, 12, 14, 15, 16, 18, 19, 20 | 11, 12, 14, 15, 16 |

| 2X | 14, 15, 16, 18, 19, 20, 22, 24 | 14, 15, 16, 18, 19 |

| 3 | 18, 19, 20, 22, 24, 25, 28, 30 | 18, 19, 20, 22, 24, 25 |

| 3X | 18, 19, 20, 22, 24, 25, 28, 30 | 18, 19, 20, 22, 24, 25 |

| 4X | 19・20・22・24・25・28・30・32・35・38・40・42・45・48・50 | 19, 20, 22, 24, 25, 28, 30, 32, 35, 38, 40, 42, 45 |

| 尺寸 | 符合旧JIS标准的轴孔尺寸A | 符合旧JIS标准的轴孔尺寸K |

|---|---|---|

| 1X | 8, 10, 11, 12, 14 | 8, 10, 11, 12 |

| 2 | 11, 12, 14, 15, 16, 18, 19, 20 | 11, 12, 14, 15, 16 |

| 2X | 14, 15, 16, 18, 19, 20, 22, 24 | 14, 15, 16, 18, 19, 20 |

| 3 | 18, 19, 20, 22, 24, 25, 28, 30 | 18, 19, 20, 22, 24, 25 |

| 3X | 18, 19, 20, 22, 24, 25, 28, 30 | 18, 19, 20, 22, 24, 25 |

| 4X | 19・20・22・24・25・28・30・32・35・38・40・42・45・48・50 | 19, 20, 22, 24, 25, 28, 30, 32, 35, 38, 40, 42, 45 |

※孔径φ8mm没有键槽。

※孔加工规格如下所示。

| 尺寸 | K1 | B | C | C1 | D | E | F | G | H | I | J | L | N | M1 | M2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1X | 12.5 | 20 | 30 | 23 | 42 | 15 | 30 | 5 | 25 | 22 | 3 | 50 | 6 | 2-M4 | 2-M4 |

| 2 | 16.5 | 25 | 41 | 32.5 | 55 | 20 | 35 | 11 | 35 | 32 | 5 | 66 | 7 | 2-M5 | 2-M5 |

| 2X | 20.5 | 31 | 45 | 34 | 65 | 25 | 40 | 11 | 40 | 38 | 5 | 76 | 8 | 2-M5 | 2-M5 |

| 3 | 25.5 | 38 | 53 | 40 | 75 | 30 | 50 | 11 | 45 | 45 | 5 | 91 | 10 | 2-M6 | 2-M6 |

| 3X | 25.5 | 36 | 85 | 41 | 75 | 30 | 80 | 11 | 45 | 45 | 6 | 121 | 10 | 2-M6 | 2-M6 |

| 4X | - | 46 | 95 | - | 120 | 35 | 90 | 16 | 80 | 80 | 8 | 141 | 12 | 2-M10 | 2-M10 |

【标准孔加工规格】

| 符合旧JIS(2种)标准 | 符合新JIS标准 | 支持新标准电动机 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 孔径公称 | 孔径 φA,φK -1 | 符合旧JIS(2种)标准 键槽宽度 W | 符合旧JIS(2种)标准 键槽高度 T | 孔径公称 | 孔径 φA,φK | 键槽宽度 W | 键槽高度 T | 孔径公称 | 孔径 φA,φK G7 | 键槽宽度 W | 键槽高度 T |

| 公差 | H7 | E9 | +0.50 | 公差 | H7 | H9 | +0.50 | 公差 | G7 | H9 | +0.50 |

| 8 | 8+0.0150 | - | - | - | - | - | - | - | - | - | - |

| 10 | 10+0.0150 | 4+0.050+0.020 | 11.5 | 10H | 10+0.0150 | 4+0.0300 | 11.8 | - | - | - | - |

| 11 | 11+0.0180 | 4+0.050+0.020 | 12.5 | 11H | 11+0.0180 | 4+0.0300 | 12.8 | - | - | - | - |

| 12 | 12+0.0180 | 4+0.050+0.020 | 13.5 | 12H | 12+0.0180 | 4+0.0300 | 13.8 | - | - | - | - |

| 14 | 14+0.0180 | 5+0.050+0.020 | 16.0 | 14H | 14+0.0180 | 5+0.0300 | 16.3 | 14N | 14+0.024+0.006 | 5+0.0300 | 16.0 |

| 15 | 15+0.0180 | 5+0.050+0.020 | 17.0 | 15H | 15+0.0180 | 5+0.0300 | 17.3 | - | - | - | - |

| 16 | 16+0.0180 | 5+0.050+0.020 | 18.0 | 16H | 16+0.0180 | 5+0.0300 | 18.3 | - | - | - | - |

| 18 | 18+0.0180 | 5+0.050+0.020 | 20.0 | 18H | 18+0.0180 | 6+0.0300 | 20.8 | - | - | - | - |

| 19 | 19+0.0210 | 5+0.050+0.020 | 21.0 | 19H | 19+0.0210 | 6+0.0300 | 21.8 | 19N | 19+0.028+0.007 | 6+0.0300 | 21.5 |

| 20 | 20+0.0210 | 5+0.050+0.020 | 22.0 | 20H | 20+0.0210 | 6+0.0300 | 22.8 | - | - | - | - |

| 22 | 22+0.0210 | 7+0.061+0.025 | 25.0 | 22H | 22+0.0210 | 6+0.0300 | 24.8 | - | - | - | - |

| 24 | 24+0.0210 | 7+0.061+0.025 | 27.0 | 24H | 24+0.0210 | 8+0.0360 | 27.3 | 24N | 24+0.028+0.007 | 8+0.0360 | 27.0 |

| 25 | 25+0.0210 | 7+0.061+0.025 | 28.0 | 25H | 25+0.0210 | 8+0.0360 | 28.3 | - | - | - | - |

| 28 | 28+0.0210 | 7+0.061+0.025 | 31.0 | 28H | 28+0.0210 | 8+0.0360 | 31.3 | 28N | 28+0.028+0.007 | 8+0.0360 | 31.0 |

| 30 | 30+0.0210 | 7+0.061+0.025 | 33.0 | 30H | 30+0.0210 | 8+0.0360 | 33.3 | - | - | - | - |

| 32 | 32+0.0250 | 10+0.061+0.025 | 35.5 | 32H | 32+0.0250 | 10+0.0360 | 35.3 | - | - | - | - |

| 35 | 35+0.0250 | 10+0.061+0.025 | 38.5 | 35H | 35+0.0250 | 10+0.0360 | 38.3 | - | - | - | - |

| 38 | 38+0.0250 | 10+0.061+0.025 | 41.5 | 38H | 38+0.0250 | 10+0.0360 | 41.3 | 38N | 38+0.034+0.009 | 10+0.0360 | 41.0 |

| 40 | 40+0.0250 | 10+0.061+0.025 | 43.5 | 40H | 40+0.0250 | 12+0.0430 | 43.3 | - | - | - | - |

| 42 | 42+0.0250 | 10+0.061+0.025 | 45.5 | 42H | 42+0.0250 | 12+0.0430 | 45.3 | 42N | 42+0.034+0.009 | 12+0.0430 | 45.0 |

| 45 | 45+0.0250 | 12+0.075+0.032 | 48.5 | 45H | 45+0.0250 | 14+0.0430 | 48.8 | - | - | - | - |

| 48 | 48+0.0250 | 12+0.075+0.032 | 51.5 | 48H | 48+0.0250 | 14+0.0430 | 51.8 | 48N | 48+0.034+0.009 | 14+0.0430 | 51.5 |

| 50 | 50+0.0250 | 12+0.075+0.032 | 53.5 | 50H | 50+0.0250 | 14+0.0430 | 53.8 | - | - | - | - |

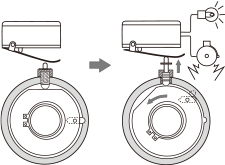

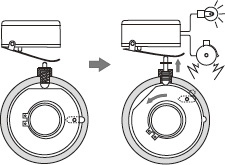

如果无人操作或遥控操作的机器·装置等过载,需要自动切断电源及鸣响警铃的装置。在这种情况下,可通过在转矩拉紧器安装该信号销来检测过载。

如果过载,输入侧和输出侧被分开,在转矩拉紧器毂部分的凸轮机构作用下,信号销向半径方向突出。利用此动作,可通过极限开关切断电源及鸣响警铃等。

在这种情况下,请务必将外壳作为输入侧使用。

无法将标准产品改造成带信号销。如果需要带信号销,订购时请在型号末尾指示-P。

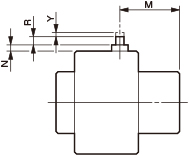

【尺寸】

| 尺寸 | M | Y | R | N |

|---|---|---|---|---|

| 1X | 24 | 1.5 | 6.5 | 5.5 |

| 2 | 29 | 2.5 | 5 | 4.5 |

| 2X | 36 | 2.5 | 5 | 4.5 |

| 3 | 43 | 2.5 | 5 | 4.5 |

| 3X | 42 | 2.5 | 5 | 4.5 |

| 4X | 55 | 2.5 | 5 | 2 |

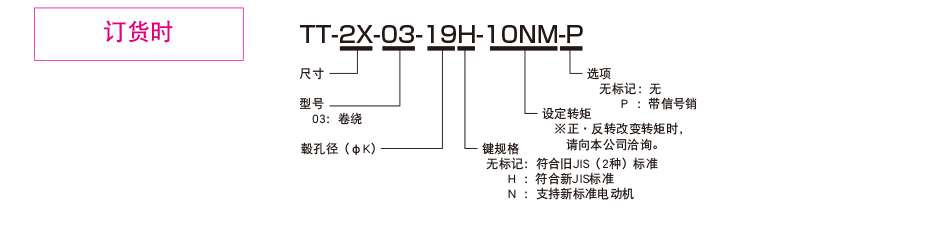

TT-□-03型

【规格】

| 型 号 | 尺寸 | 设定转矩值[N•m] | 最高转速[min-1] | 转动惯量[kg•m2] | 质量[kg] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 弹簧颜色分类 | |||||||||||||

| 无色 | 蓝色 | 红色 | 黄色 | 白色 | 灰色 | 绿色 | 棕色* | 无色* | |||||

| TT-1X-03 | 1X | 0.2 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 1800 | 0.09×10-3 | 0.4 |

| TT-2-03 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 1800 | 0.31×10-3 | 0.8 |

| TT-2X-03 | 2X | 2 | 3 | 5 | 8 | 10 | 12 | 15 | 18 | 20 | 1800 | 0.66×10-3 | 1.1 |

| TT-3-03 | 3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 1800 | 1.59×10-3 | 1.7 |

| TT-3X-03 | 3X | 10 | 16 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 1800 | 2.43×10-3 | 3.0 |

| TT-4X-03 | 4X | 20 | 30 | 50 | 80 | 100 | 120 | 150 | 180 | 200 | 500 | 15.8×10-3 | 6.5 |

※上表设定的转矩值为转速1500min-1时的数值。

※*部分的转矩需要耐久性时,请增大尺寸。

【尺寸】

| 尺寸 | 符合新JIS标准的轴孔尺寸K |

|---|---|

| 1X | 10, 11, 12 |

| 2 | 11, 12, 14, 15, 16 |

| 2X | 14, 15, 16, 18, 19 |

| 3 | 18, 19, 20, 22, 24, 25 |

| 3X | 18, 19, 20, 22, 24, 25 |

| 4X | 19, 20, 22, 24, 25, 28, 30, 32, 35, 38, 40, 42, 45 |

| 尺寸 | 符合旧JIS标准的轴孔尺寸K |

|---|---|

| 1X | 8, 10, 11, 12 |

| 2 | 11, 12, 14, 15, 16 |

| 2X | 14, 15, 16, 18, 19, 20 |

| 3 | 18, 19, 20, 22, 24, 25 |

| 3X | 18, 19, 20, 22, 24, 25 |

| 4X | 19, 20, 22, 24, 25, 28, 30, 32, 35, 38, 40, 42, 45 |

※孔径φ8mm没有键槽。

※孔加工规格如下所示。

| 尺寸 | K1 | B | D | E | F | H | N | L | P | S | T | U | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1X | 12.5 | 34 | 42 | 20 | 35 | 30 | 25 | 55 | 16 | 14 | 2.5 | 4 | 2-M4 |

| 2 | 16.5 | 38 | 55 | 25 | 40 | 40 | 30 | 65 | 20 | 18 | 3 | 5 | 2-M5 |

| 2X | 20.5 | 40 | 65 | 25 | 45 | 45 | 31 | 70 | 20 | 18 | 3 | 5 | 2-M5 |

| 3 | 25.5 | 52.5 | 75 | 35 | 55 | 60 | 45 | 90 | 30 | 28 | 4 | 7 | 2-M6 |

| 3X | 25.5 | 75 | 75 | 35 | 90 | 60 | 45 | 125 | 30 | 28 | 4 | 7 | 2-M6 |

| 4X | 46 | 100 | 120 | 50 | 90 | 85 | 57 | 140 | 45 | 40 | 4.5 | 12 | 2-M8 |

※外径键(旧JIS 2种)及止动环为附带部件。

【标准孔加工规格】

| 符合旧JIS(2种)标准 | 符合新JIS标准 | 支持新标准电动机 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 孔径公称 | 孔径 φA,φK -1 | 符合旧JIS(2种)标准 键槽宽度 W | 符合旧JIS(2种)标准 键槽高度 T | 孔径公称 | 孔径 φA,φK | 键槽宽度 W | 符合键槽高度 T | 孔径公称 | 孔径 φA,φK G7 | 键槽宽度 W H9 | 键槽高度 T |

| 公差 | H7 | E9 | +0.50 | 公差 | H7 | H9 | +0.50 | 公差 | G7 | +0.50 | |

| 8 | 8+0.0150 | - | - | - | - | - | - | - | - | - | - |

| 10 | 10+0.0150 | 4+0.050+0.020 | 11.5 | 10H | 10+0.0150 | 4+0.0300 | 11.8 | - | - | - | - |

| 11 | 11+0.0180 | 4+0.050+0.020 | 12.5 | 11H | 11+0.0180 | 4+0.0300 | 12.8 | - | - | - | - |

| 12 | 12+0.0180 | 4+0.050+0.020 | 13.5 | 12H | 12+0.0180 | 4+0.0300 | 13.8 | - | - | - | - |

| 14 | 14+0.0180 | 5+0.050+0.020 | 16.0 | 14H | 14+0.0180 | 5+0.0300 | 16.3 | 14N | 14+0.024+0.006 | 5+0.0300 | 16.0 |

| 15 | 15+0.0180 | 5+0.050+0.020 | 17.0 | 15H | 15+0.0180 | 5+0.0300 | 17.3 | - | - | - | - |

| 16 | 16+0.0180 | 5+0.050+0.020 | 18.0 | 16H | 16+0.0180 | 5+0.0300 | 18.3 | - | - | - | - |

| 18 | 18+0.0180 | 5+0.050+0.020 | 20.0 | 18H | 18+0.0180 | 6+0.0300 | 20.8 | - | - | - | - |

| 19 | 19+0.0210 | 5+0.050+0.020 | 21.0 | 19H | 19+0.0210 | 6+0.0300 | 21.8 | 19N | 19+0.028+0.007 | 6+0.0300 | 21.5 |

| 20 | 20+0.0210 | 5+0.050+0.020 | 22.0 | 20H | 20+0.0210 | 6+0.0300 | 22.8 | - | - | - | - |

| 22 | 22+0.0210 | 7+0.061+0.025 | 25.0 | 22H | 22+0.0210 | 6+0.0300 | 24.8 | - | - | - | - |

| 24 | 24+0.0210 | 7+0.061+0.025 | 27.0 | 24H | 24+0.0210 | 8+0.0360 | 27.3 | 24N | 24+0.028+0.007 | 8+0.0360 | 27.0 |

| 25 | 25+0.0210 | 7+0.061+0.025 | 28.0 | 25H | 25+0.0210 | 8+0.0360 | 28.3 | - | - | - | - |

| 28 | 28+0.0210 | 7+0.061+0.025 | 31.0 | 28H | 28+0.0210 | 8+0.0360 | 31.3 | 28N | 28+0.028+0.007 | 8+0.0360 | 31.0 |

| 30 | 30+0.0210 | 7+0.061+0.025 | 33.0 | 30H | 30+0.0210 | 8+0.0360 | 33.3 | - | - | - | - |

| 32 | 32+0.0250 | 10+0.061+0.025 | 35.5 | 32H | 32+0.0250 | 10+0.0360 | 35.3 | - | - | - | - |

| 35 | 35+0.0250 | 10+0.061+0.025 | 38.5 | 35H | 35+0.0250 | 10+0.0360 | 38.3 | - | - | - | - |

| 38 | 38+0.0250 | 10+0.061+0.025 | 41.5 | 38H | 38+0.0250 | 10+0.0360 | 41.3 | 38N | 38+0.034+0.009 | 10+0.0360 | 41.0 |

| 40 | 40+0.0250 | 10+0.061+0.025 | 43.5 | 40H | 40+0.0250 | 12+0.0430 | 43.3 | - | - | - | - |

| 42 | 42+0.0250 | 10+0.061+0.025 | 45.5 | 42H | 42+0.0250 | 12+0.0430 | 45.3 | 42N | 42+0.034+0.009 | 12+0.0430 | 45.0 |

| 45 | 45+0.0250 | 12+0.075+0.032 | 48.5 | 45H | 45+0.0250 | 14+0.0430 | 48.8 | - | - | - | - |

| 48 | 48+0.0250 | 12+0.075+0.032 | 51.5 | 48H | 48+0.0250 | 14+0.0430 | 51.8 | 48N | 48+0.034+0.009 | 14+0.0430 | 51.5 |

| 50 | 50+0.0250 | 12+0.075+0.032 | 53.5 | 50H | 50+0.0250 | 14+0.0430 | 53.8 | - | - | - | - |

如果无人操作或遥控操作的机器·装置等过载,需要自动切断电源及鸣响警铃的装置。在这种情况下,可通过在转矩拉紧器安装该信号销来检测过载。

如果过载,输入侧和输出侧被分开,在转矩拉紧器毂部分的凸轮机构作用下,信号销向半径方向突出。利用此动作,可通过极限开关切断电源及鸣响警铃等。

在这种情况下,请务必将外壳作为输入侧使用。

无法将标准产品改造成带信号销。如果需要带信号销,订购时请在型号末尾指示-P。

【尺寸】

| 尺寸 | M | Y | R | N |

|---|---|---|---|---|

| 1X | 47 | 1.5 | 6.5 | 5.5 |

| 2 | 56 | 2.5 | 5 | 4.5 |

| 2X | 60 | 2.5 | 5 | 4.5 |

| 3 | 79 | 2.5 | 5 | 4.5 |

| 3X | 114 | 2.5 | 5 | 4.5 |

| 4X | 125 | 2.5 | 5 | 2 |